With the increase in people's attention to health, biomedical materials have developed rapidly. According to statistics, the world's total sales of medical devices in 2020 reached US$477.4 billion, with a compound growth rate of 5.6%, which has become a pillar industry of the world economy. In recent years, with the emergence of a number of innovative technologies, materials science has developed rapidly, and medical polymer materials have gradually become widely used and widely used materials. Among them, the overall market share of biomedical materials and products was 40%, reaching US$191 billion, and the proportion continued to grow, making it the sunrise field in the sunrise industry.

As a new type of medical implant material, polyether ether ketone (PEEK) stands out among many medical materials due to its excellent characteristics. According to Radiant Insightsanalysts Consulting, the world PEEK market will continue to develop at an average annual compound growth rate of 10.43% per year from 2017 to 2022.

So, what exactly is polyether etherketone (PEEK)? What kind of excellent performance does it have

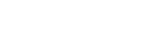

What is PEEK?

Application of PEEK in the medical field

1. Biocompatibility - non-toxic, safe but not allergic

First, PEEK is excellent in biocompatibility and has no other side effects.

2. Elastic modulus - no stress shielding, surrounding bones are healthier; Wolfe's law points out that bones grow where they are needed and absorb where they are not needed, that is, bone growth, absorption, and reconstruction are all related to the stress state of the bone.

The elastic modulus of PEEK is very close to that of the bones, and the stresses on the bones are not entirely borne by the implant, so there is no so-called stress shielding phenomenon, which makes the bones around the implant healthier.

3. Visibility—Study and observation are more convenient

PEEK has X-ray penetration, no artifacts on X-rays, and can easily track the healing process after surgery, effectively monitoring bone growth and healing.

PEEK maxillofacial and skull implants to avoid the embarrassment of cold winter and hot summer

|  |

A very typical example of archaeology of skull repair materials can be traced back to 2000 BC: This Peruvian skull was found to have a left forehead defect covered by a 1mm thick gold disc. This may be the skull repair material that has been discovered at present. The early skull repair document records came from Fallopius in the 16th century.

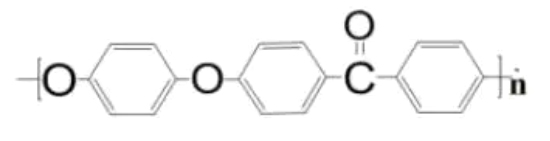

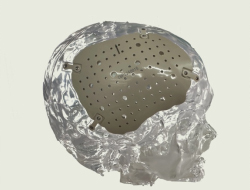

As we all know, the human body has high requirements for implanted materials. The implanted materials need to remain in the human body for a long time, so they have high requirements for their biocompatibility, fatigue strength, wear resistance, corrosion resistance and other characteristics. Metals have long been a must-have for implantable materials. Compared with commonly used titanium alloys, PEEK's physical properties are close to that of human bones, have a strong texture, and have an elastic modulus similar to that of cortical bones. Even if it is impacted, it will not cause depression or deformation, which can well protect patients after craniotomy. Some scholars abroad have also used polyether etherketone materials for surgery for patients with skull defects in the maxillofacial, temporal orbital, and forehead. The aesthetic effect of skull repair is satisfactory and brain function has been well restored.

To sum up, polyether ether ketone material is one of the excellent choices for craniomaxillofacial bone repair surgery.